How To Be 50x More Productive

Curated from: medium.com

Ideas, facts & insights covering these topics:

24 ideas

·6.17K reads

18

Explore the World's Best Ideas

Join today and uncover 100+ curated journeys from 50+ topics. Unlock access to our mobile app with extensive features.

" In the decade after Frederick Winslow Taylor first looked at work and studied it, the productivity of the manual worker began its unprecedented rise… On this achievement rest all of the economic and social gains of the 20th century ”

PETER DRUCKER

29

403 reads

“ At the peak of his celebrity in the early twentieth century, Taylor gave lectures around the country and was as famous as Edison or Ford ”

ROBERT KANIGEL

28

350 reads

Who Is Frederick Winslow Taylor?

Taylor was a high achiever. He was accepted to Harvard and had plans to become a lawyer just like his father. But then, he started having sharp headaches was later diagnosed with the eye condition of Astigmatism.

So, by a weird quirk of fate, Taylor went to the shop floor as an apprentice machinist rather than Harvard to become a lawyer.

As a machinist, he noticed that the workmen were not working nearly as hard as they could. So he started to experiment with how worker productivity could be improved.

29

317 reads

“ My head was full of wonderful and great projects to simplify the processes, to design new machinery, to revolutionize the methods of the whole establishment. ”

TAYLOR

29

309 reads

What Caused The 50x Manual Worker Revolution Boom Is Surprising

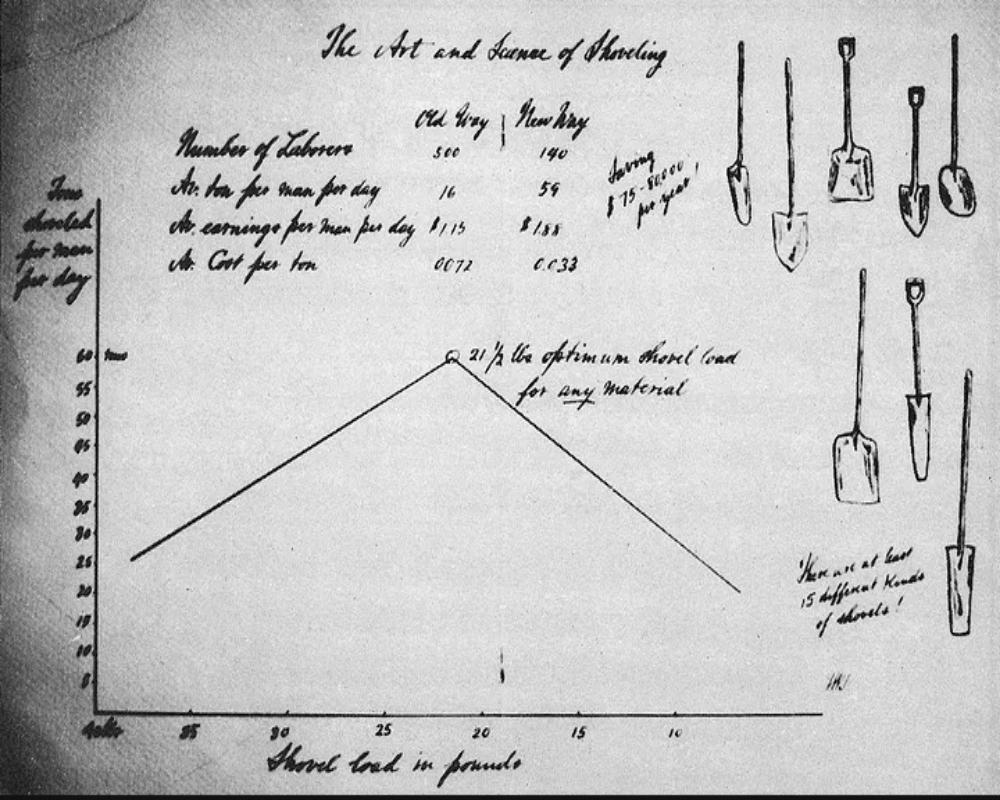

In 1898, Taylor was hired by Bethlehem Steel to make its 600 shovelers more productive. So, he endeavored to create a science of shoveling.

First, Taylor questioned basic assumptions:

For a first-class shoveler there is a given shovel load at which he will do his biggest day’s work. What is this shovel load? Will a first-class man do more work per day with a shovel load of 5 pounds, 10 pounds, 15 pounds, 20, 25, 30, or 40 pounds?

28

310 reads

Answer To That Question

Next, he answers these questions with time and motion studies combined with experiments on:

- Kinds of shovels: They settled on 8–10.

- Shoveling techniques: Testing various distances, weights, and heights.

- Management systems: Training employees on the scientific method so they can perform experiments. Standardizing the winning experiments into the company processes and culture. Providing bonuses to individuals rather than having a common group wage.

29

292 reads

What Was The End Result Of These Shoveling experiments?

After much experimentation, he found the optimal shovel load was 21 pounds.

The output per man doubled. As a result, employees earned 35% more on average.

All of this from turning the simple act of shoveling into a science.

28

259 reads

The Boot Principle

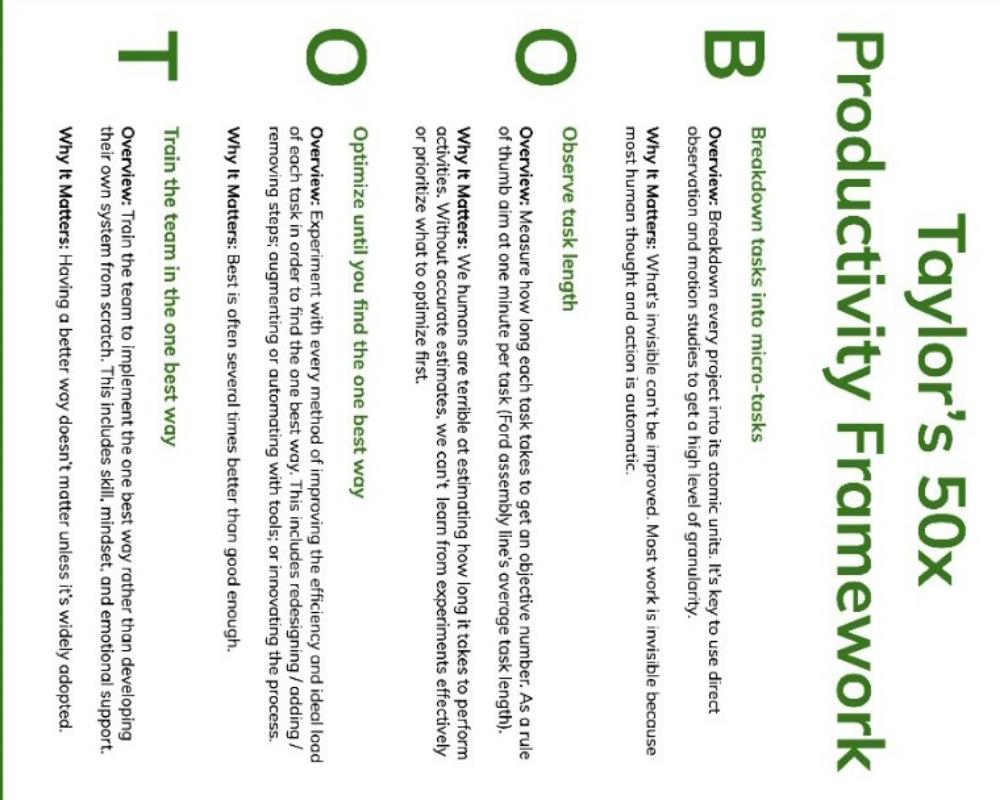

Taylor, after much experimentation & application like the above example, created a framework called '50X Productivity Framework'.

The pnemonic BOOT was used to explain the 4 step procedure to increase productivity

30

272 reads

B: Breakdown Tasks Into Smaller Tasks

Overview:

Breakdown every project into its atomic units. It's key to use directo bservation and motion studies to get a high level of granularity.

Why It Matters:

What's invisible can't be improved. Most work is invisible because most human thought and action is automatic.

32

255 reads

O: Observe Task Length

Overview:

Measure how long each task takes to get an objective number. As a rule of thumb aim at one minute per task (Ford assembly line's average task length).

Why It Matters:

We humans are terrible at estimating how long it takes to perform activities. Without accurate estimates, we can't learn from experiments effectively or prioritize what to optimize first.

29

226 reads

O: Optimize Until You Find The One Best Way

Overview:

Experiment with every method of improving the efficiency and ideal load of each task in order to find the one best way. This includes redesigning/adding/ removing steps; augmenting or automating with tools; or innovating the process.

Why It Matters: Best is often several times better than good enough.

29

214 reads

T: Train The Team In The One Best Way

Overview:

Train the team to implement the one best way rather than developing their own system from scratch. This includes skill, mindset, and emotional support.

Why It Matters: Having a better way doesn't matter unless it's widely adopted.

29

192 reads

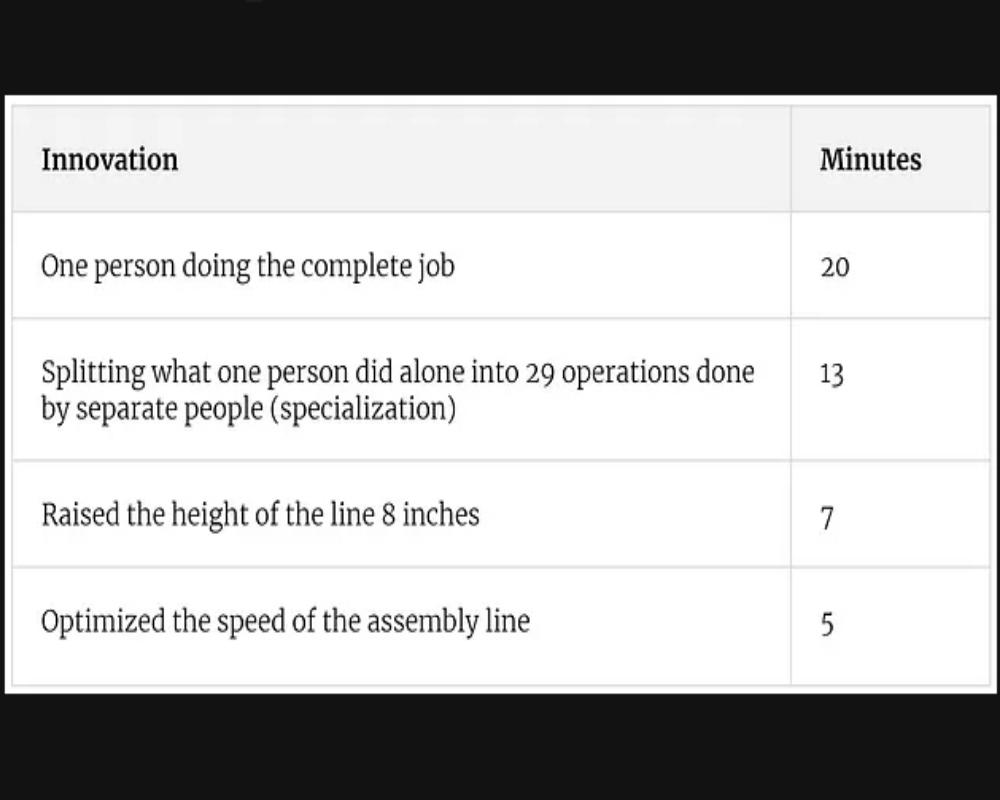

Optimization Example

One of my favorite optimization examples from Ford’s autobiography is a step-by-step overview of how he turned a 20-minute assembly job into a 5-minute one (a 4x improvement)

30

222 reads

Taylor's Universal Productivity paradigm

Small productivity gains aren’t frivolous. Amazing productivity gains come from small hacks, which individually seem frivolous, but together add up to mind-boggling change.

31

215 reads

“ Technology alone is rarely enough to create significant benefits. ”

GEORGIOS PETROPOULOS & ERIK BRYNJOLFSSON

29

205 reads

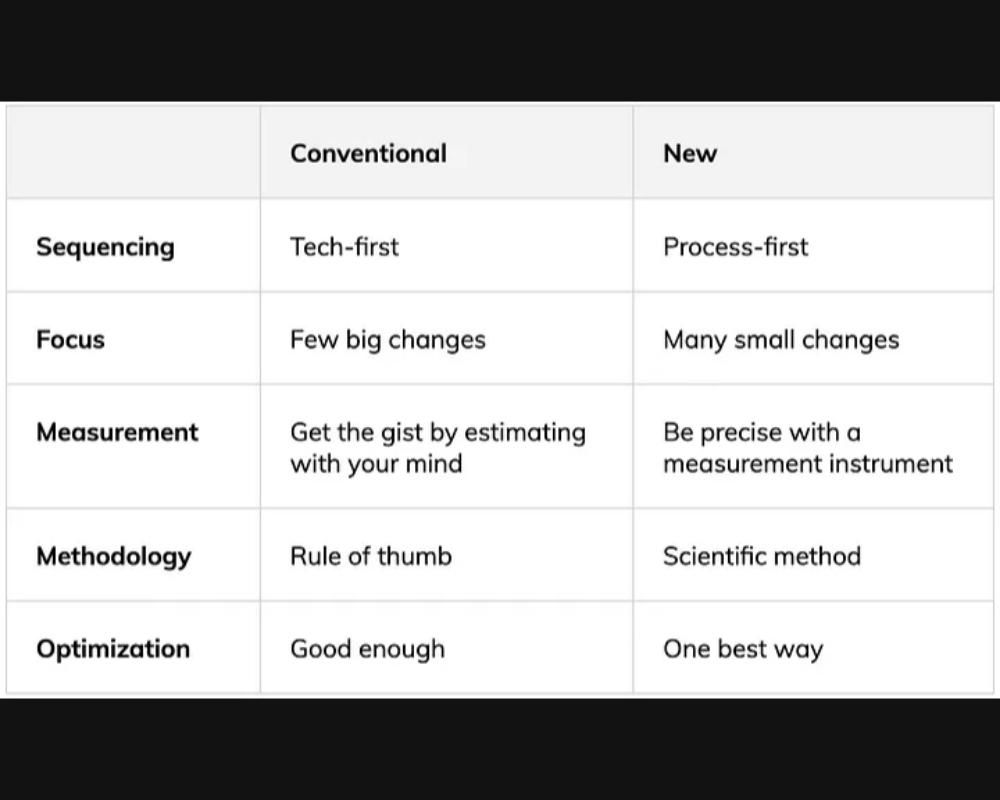

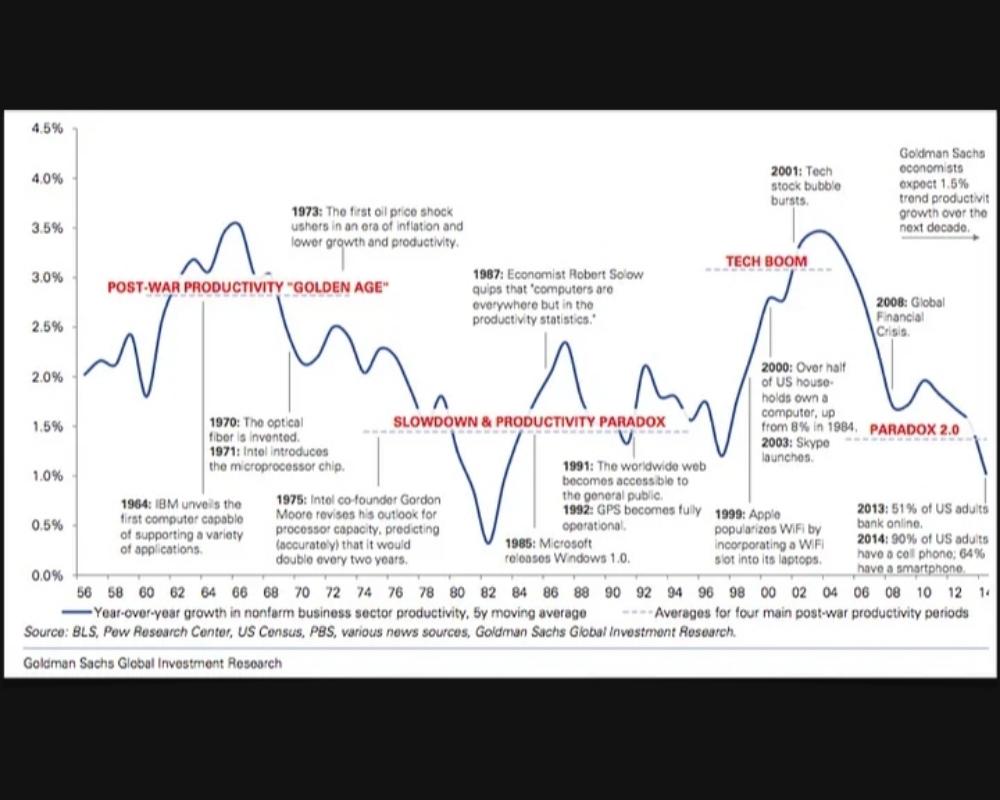

Does Technology Boost Productivity?

The industrial revolution left us with the suggestion that the cause of the productivity boost was technology. Seeing the productivity graph of the U.S, we can conclude that productivity depends on the person, not his tools.

29

184 reads

Shallow & Deep Productivity

Optimizing the process first is deep productivity. It has the most leverage, but requires rethinking one’s whole production process, which takes a lot of time.

Finding quick hacks using the latest tools while using an unoptimized process is shallow productivity. It is like putting lipstick on a pig. It provides quick bursts of productivity, but is not the ideal approach long-term.

30

184 reads

Information Overload

One of the hallmark studies of manual work industrialization is finding the optimal shovel load weight of 21 lbs. If workers attempt to carry too heavy of a load, they risk getting exhausted too quickly and getting injured. Whereas, with a lighter load, their overall productivity per day is higher.

Similarly, researchers have made the case that there is an “optimal” load for knowledge consumption and that if we consume too much there are real consequences. Yet, there is no science on the ideal load for knowledge consumption.

30

159 reads

“ Info overload often leads to stress, inefficiency, and mistakes that can result in poor decisions, bad analysis, and/or miscommunication ”

MIT & STANFORD RESEARCHERS

32

170 reads

“ Today’s knowledge workers waste a third of their day, every day, on activities that could be reduced, consolidated, or eliminated altogether ”

TAYLOR

30

163 reads

Conclusion

Productivity depends on you, not on the tools you use. To increase productivity, planning is important. Identify each aspect of your work or personal life and try to optimize it by making small changes. Use Taylor's Universal Productivity Paradigm & BOOT Principle to increase your productivity.

30

169 reads

IDEAS CURATED BY

CURATOR'S NOTE

I tried to summarize a 30 minute article on Taylor, Ford & The Productivity Experiment on medium in 10 minutes. I found the article very fascinating, so why not post it on Deepstash?

“

Similar ideas

7 ideas

4 ideas

11 ideas

Read & Learn

20x Faster

without

deepstash

with

deepstash

with

deepstash

Personalized microlearning

—

100+ Learning Journeys

—

Access to 200,000+ ideas

—

Access to the mobile app

—

Unlimited idea saving

—

—

Unlimited history

—

—

Unlimited listening to ideas

—

—

Downloading & offline access

—

—

Supercharge your mind with one idea per day

Enter your email and spend 1 minute every day to learn something new.

I agree to receive email updates